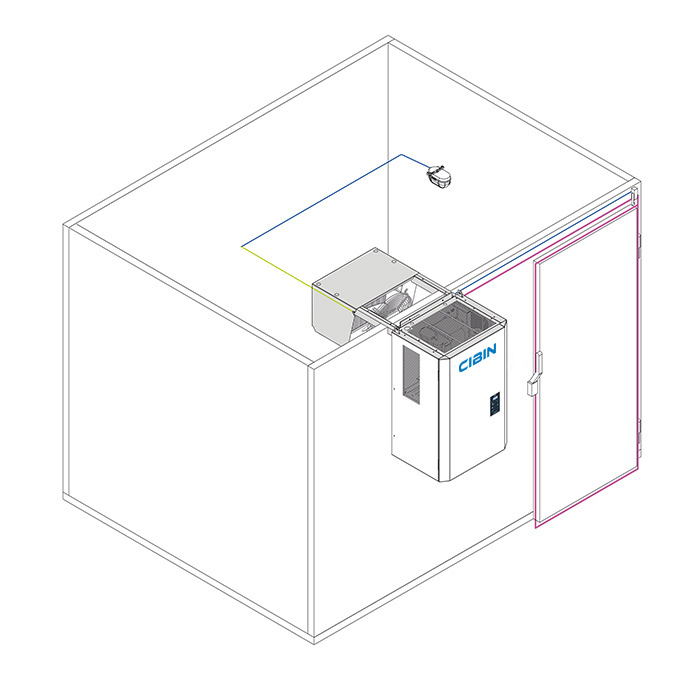

Installation example

The new machine R290 range

Ultra-low GWP refrigerants

The new Cibin monoblock range uses natural refrigerants with very low GWP. With a GWP of only 3, R290 is the future solution for low and medium temperature small-scale commercial refrigeration.

Our tests have also shown a significant advantage in terms of TEWI, which depends both on the GWP and on all the design solutions adopted

Charge limit lower than 150g

R290 is classified A3, meaning it is non-toxic but highly flammable. Depending on the application and available volume, it is possible to calculate a maximum refrigerant charge which makes the machine safe from any accidents related to fluid flammability. There are application limits for refrigerant charge of 150g as 150g is never sufficient to create a potentially dangerous atmosphere.

Cibin R290 monoblocks are all charged with 150g (or less) in the refrigeration circuit.

Technical characteristics:

Inverter

technology

Inverter technology allows the refrigeration unit to understand the actual cooling capacity requirement. The machine, through sophisticated algorithms, calculates the optimal operating point at various working conditions and adjusts the compressor’s rotation speed in order to optimise efficiency and cooling output. The aim of the unit will always be to work at the lowest possible speed in order to limit pressure and work at higher COP.

Electronic

Valve

The electronic valve provides the best possible control of the evaporation pressure. The step-by-step control regulates the refrigerant flow rate at the evaporator inlet, ensuring the correct supply of refrigerant according to the various operating conditions. The exchange surface will always yield the maximum possible cooling capacity.

Condensation

Control

The condensers are equipped with permanent magnet fans with 0-10 control. This type of fan, the electronic board and the machine’s control logic make it possible to best control the condensing pressure to maximise the machine’s total COP while reducing the electrical power absorbed by the fan to the indispensable minimum.

Condenser

dT 10K

Machine condensers are sized to work with a temperature difference of 10K at nominal conditions. This allows the machine to work with a lower pressure ratio and therefore higher efficiency. Such sizing also means that the unit can work at a higher ambient temperature while remaining completely safe.

New

Electronics

The new PRO family monoblocks are controlled by a new, state-of-the-art electronic board. The electronic board, through sophisticated algorithms, can manage the inverter, valves and fans in order to guarantee the COP of the machine and is able to make available to the operator a lot of useful information on the operation and programming of the machine.

Growed

Tubes

The exchanger pipes are internally rifled. This makes it possible to increase the exchange surface between the refrigerant and the inner wall of the pipe, improving exchange efficiency and reducing the dimensions of the coils for the same heat output. An exchanger with a grooved pipe can improve exchange efficiency by up to 25% compared to traditional smooth pipes.

Water

Condensation

Water condensation involves a brazed welded exchanger and a flow control valve. Water-cooled means that the condensing pressure of the machine will be be limited and it will work at more favourable and constant operating conditions over time.

Cataphoresis

painting

This type of painting used on evaporators is particularly suitable for use in aggressive environments.

Models

R290

* Max ambient temperature: + 43°CTa: Ambient temperature

Tc: Cold room temperature