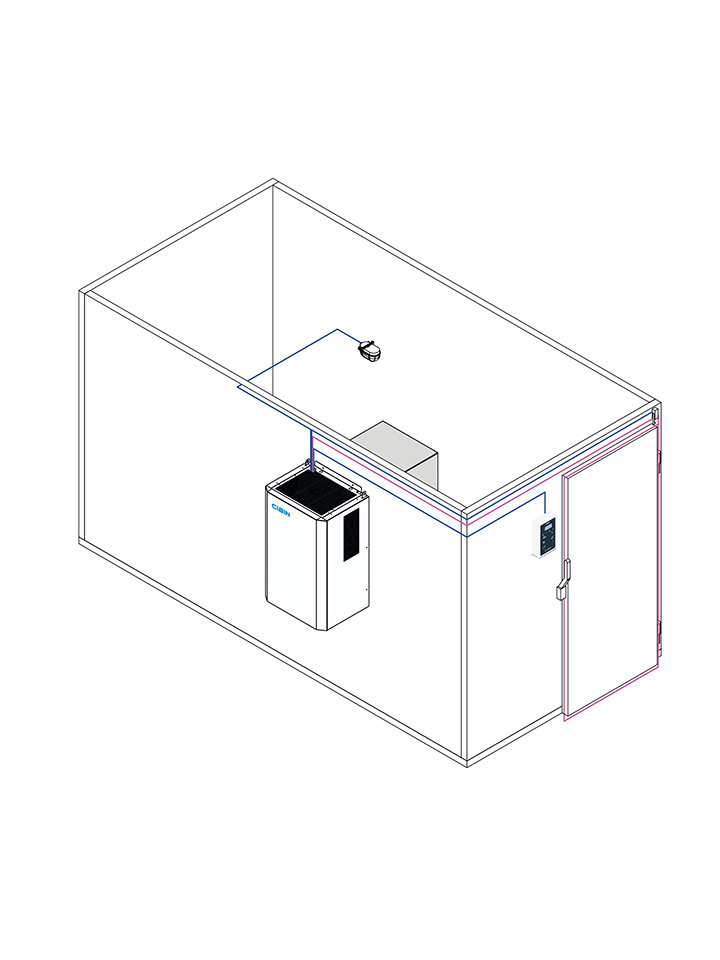

NORCA is a refrigerating system for slot-in installation. Its monobloc structure makes it possible to create a

Installation example

R455: The new eco-friendly refrigerant range

Ultra-low GWP refrigerants

The new Cibin monoblock range use the latest generation ultra-low GWP refrigerants. With a GWP of only 146, R455A is the definitive solution for future low/medium temperature commercial and industrial refrigeration.

After multiple tests and studies based on the entire cold chain, it has been shown that the TEWI (Total equivalent warming impact) of machines operating with R455A is significantly lower thanks both to the refrigerant, COP and the ease of managing the machines, which are more user-friendly compared to old R404A machines.

Safety

The refrigerant used is composed of a mildly flammable azeotropic mixture (A2L in accordance with ISO 817). However, the use of R455A is made safe (in compliance with the principal safety standards) due to the specific flammability properties of the refrigerant, which include:

a) Relatively high lower flammability limit equal to 11,8% (LFL);

b) Relatively low upper flammability limit compared to the low

flammability limit 12,9% (UFL);

c) Minimum ignition energy more than 1000 times higher

than propane;

d) Flame propagation speed lower than 1,5cm/s.

Technical characteristics:

Standard configuration

• Sealed circuit

• Hermetic compressor

• Anti-vibration compressor brackets

• Crankcase resistance *

• Air condensation

• Galvanized powder coated sheet steel body

• Evaporator with cataphoretically painting

• Evaporator body of aluminium-magnesium alloy

• Evaporator of copper pipes and aluminium fins

• Condenser of copper pipes and aluminium fins

• Automatic restarting high pressure switch to weld

• Compressor timer management to avoid too near start-ups

• Axial fan

• Condensation control device

• Thermic compressor protection

• General magnete-thermal protection *

• Thermostatic expansion valve with external equalization *

• Suction pressure relief valve (only for low temperature models)

• Dehydrator filter

• Suction-side liquid separator*

• Defrost hot gas solenoid valve

• Automatic hot gas defrosting

• Condensation outlet siphon

• Condensation outlet resistor (only for low temperature models)

• Cold room ceiling light

• Ambient temperature probe

• Defrosting end temperature probe

• Condensation control temperature probe

• Connecting cable for door resistor with protection 4A fuse

(only for low temperatures models) and related protection with fuses

• Connecting cable for door micro switch to turn off the system and to turn

on the light at door opening

• Free relay for transfer alarm signals

* dipende dal modello

Remote control with:

• Digital display with temperature indicator at one decimal

• On/Off switch

• Cold room light switch

• Running state display: cold – defrosting – evaporator fans – alarm status

• Programming keys

• Alarm display

• Manual defrosting key

• High temperature alarm

• Low temperature alarm

• High temperature alarm dirty condenser

• Low temperature alarm condenser

• Open door alarm

• High pressure alarm

• Defrosting end alarm because of time-out

• Alarm ambient temperature probe defect

• Alarm defrosting end temperature probe defect

• Alarm condensation control temperature probe defect

• Timer emergency running in case of these events:

– Ambient temperature probe defect

– Defrosting end temperature probe defect

– Condensation control temperature probe defect

– Cold room door open (if there is door micro switch)

• Pre-set connection for Frigotel® supervision

Optional:

Optional:

• Door micro switch

• Voltage display for machine stop in case of incorrect power supply

• Long distance option for the remote control at distances longer than 15 m

• Acoustic siren with flashing to indicate the alarm state

• Switchboard for the management of two machines in the same cold room

• Another remote control to use as slave

• Electronic module for the connection to Frigotel® supervision system

* dipende dal modello

Destined use

Destined use, intended and unintended uses

Cibin’s refrigerating equipment is classed as food and agricultural machinery (MACHINES DIRECTIVE 2006/42/EC), destined for the treatment of food products.

The machine is designed for the conservation of foods and/or “fresh” products at temperatures indicated in annexes.

It has been designed to work in ambient temperatures from +16°C to +43°C (class T).

It has been designed to maintain a set temperature in a refrigerated cold room suitable for such uses.

The machine is not designed for use in cold rooms situated outside.

The machine is not designed for installation and use in an environment where there is risk of explosion.

Any use other than that permitted shall be considered improper, and in this case the Manufacturer will decline all liability.

The machine is not designed for the conservation of products, which produce corrosive substances.

Model range

R455A

R455A – 50Hz – TN

R455A – 50Hz – BT

R455A – 50Hz – TN – W

R455A – 50Hz – BT – W

*Max ambient temperature: +43°C

Ta: Ambient temperature

Tc: Cold room temperature